#advanced PLC automation

Explore tagged Tumblr posts

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

#Advanced PLC and HMI Training Kit Pune#Advanced PLC HMI Kits Pune#Advanced Siemens PLC Kits Pune#Advanced Mitsubishi PLC Training Pune#PLC and HMI Systems Pune#Industrial Automation Training Kits Pune#PLC and HMI Training Solutions Pune#Professional PLC Training Kits Pune#Advanced Automation Training Kits Pune#Best PLC and HMI Training Kits Pune.

0 notes

Text

Advanced PLC and HMI Training Kits Manufacturer in Pune India

Leading Manufacturer and Supplier of advanced PLC and HMI training kits in Pune. Offering Siemens, Mitsubishi, and SCADA kits for hands-on industrial automation learning.

#Advanced PLC and HMI Training Kit Pune#Advanced PLC HMI Kits Pune#Advanced Siemens PLC Kits Pune#Advanced Mitsubishi PLC Training Pune#PLC and HMI Systems Pune#Industrial Automation Training Kits Pune#PLC and HMI Training Solutions Pune#Professional PLC Training Kits Pune#Advanced Automation Training Kits Pune#Best PLC and HMI Training Kits Pune.

0 notes

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

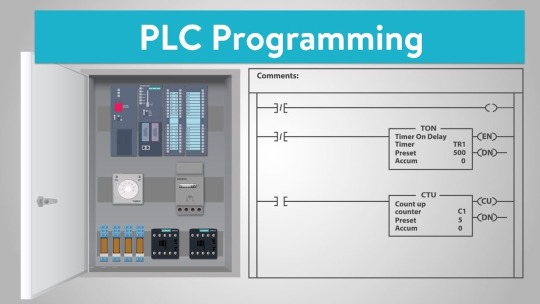

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Reliable Automation PLC and Control System Supplier in DongPu, GuangZhou

Located in DongPu, GuangZhou, we specialize in Automation PLC and Automation Control System solutions that enhance industrial efficiency. Our systems offer seamless process control, real-time monitoring, and high reliability. From machinery automation to complex production lines, we deliver advanced technologies tailored to your operation's needs across China and beyond.

0 notes

Text

Best APC 40 kVA UPS Price in India — Top Deals at OnlineUPSPrice.com

In today’s digital and power-sensitive environment, consistent and clean electricity is a necessity — not a luxury. Whether you’re running a data center, financial institution, healthcare facility, or industrial plant, a dependable uninterruptible power supply (UPS) is critical. The APC 40 kVA UPS is a high-performance solution trusted worldwide to deliver reliable backup power during outages and power fluctuations.

If you’re searching for the most competitive APC 40 kVA UPS price in India, you’ve landed at the right place — OnlineUPSPrice.com.

What is the APC 40 kVA UPS?

The APC 40 kVA UPS, part of Schneider Electric’s advanced power solutions, is designed for enterprise-level applications. It’s widely used in environments where uptime and equipment safety are essential. Built with double-conversion online technology, this UPS ensures zero transfer time during power outages and shields your systems from voltage drops, surges, spikes, and frequency shifts.

Popular APC UPS models in the 40 kVA range include:

APC Galaxy VS 40 kVA

APC Smart-UPS VT 40 kVA

Easy UPS 3M 40 kVA

These models are known for their high efficiency, scalability, remote monitoring, and compact design, making them ideal for modern, high-density infrastructure.

Top Features of APC 40 kVA UPS

✅ True Online Double Conversion: Delivers pure, regulated power without interruptions.

✅ High Efficiency: Operates at up to 96% efficiency in online mode, reducing electricity costs.

✅ Compact Design: Space-saving footprint for easier integration into server rooms or switchboards.

✅ Smart Monitoring: LCD screen and remote management via SNMP, Modbus, or network cards.

✅ Redundancy and Scalability: Parallel capability for load sharing and redundancy options.

✅ Flexible Battery Options: Compatible with VRLA, Li-ion, and external battery banks.

Who Should Use the APC 40 kVA UPS?

The APC 40 kVA UPS is suitable for businesses and institutions that demand high uptime and data integrity, including:

🏥 Hospitals & Medical Labs: Protects life-support systems, MRI machines, and critical medical equipment.

🏢 IT & Data Centers: Ensures server uptime and protects mission-critical applications.

🏭 Factories & Industrial Units: Prevents damage to PLCs, CNC machines, and automation systems.

🏦 Banks & Financial Institutions: Supports secure transaction processing and backup systems.

📡 Telecom Infrastructure: Maintains continuous service and connectivity during blackouts.

APC 40 kVA UPS Price in India — What to Expect

The APC 40 kVA UPS price in India typically starts around ₹4.5 lakhs and can go up to ₹7.5 lakhs, depending on the model, battery configuration, backup duration, and installation requirements.

Here are some of the factors that impact the final price:

🔋 Battery backup duration (10 minutes to 2 hours+)

⚡ Type of batteries (VRLA, SMF, Li-ion)

🛠️ Installation complexity

🌍 Location of delivery

🧩 Add-ons like bypass panels or SNMP cards

To get the best price and configuration tailored to your business, contact our expert sales team at OnlineUPSPrice.com.

Why Buy from OnlineUPSPrice.com?

We are one of India’s leading online platforms for UPS systems from top brands like APC, Emerson, Vertiv, Delta, Eaton, and more. Our focus is on delivering reliable products at competitive prices, backed by top-notch customer service.

Benefits of buying from us:

✔️ Lowest APC 40 kVA UPS Price Guaranteed

✔️ 100% Genuine Products with Warranty

✔️ Fast Delivery across all major cities

✔️ Expert Consultation & Installation Support

✔️ AMC, Repairs & Battery Replacement Services

✔️ Custom Solutions for Every Industry

Whether you’re setting up a new office or upgrading an existing power system, our team ensures you get the right UPS at the best price, with zero compromise on quality.

APC 40 kVA UPS — Technical Overview

SpecificationDetailsPower Rating40 kVA / 32 kWInput Voltage Range400V, 3-phaseOutput Voltage400V, 3-phaseTopologyDouble Conversion OnlineBattery TypeVRLA / External Battery BankBackup TimeCustomizable (depends on battery bank)Display PanelLCD / TouchscreenCommunicationUSB, RS-232, SNMP, ModbusEfficiencyUp to 96%DimensionsVaries by model (compact floor-standing)

Get a Free Quote Today

Looking to secure your operations with the powerful APC 40 kVA UPS? Get in touch with us for the best offers, bulk pricing, or installation advice.

📞 Call Us Now: [7829070523] 📧 Email: [Your Email Address] 🌐 Visit: https://onlineupsprice.com/emerson-vertiv-40-kva-ups/

Our team is ready to assist you with sizing, configuration, and pricing for your ideal power backup setup.

Final Words

The APC 40 kVA UPS is an industry-leading power backup system that offers high reliability, scalability, and efficiency. At OnlineUPSPrice.com, we help you make the right investment with top-tier support, genuine products, and unbeatable prices. Don’t wait for the next power cut — future-proof your business today.

0 notes

Text

Tooth Granulator: Core Equipment for Efficient Fertilizer Production

The tooth granulator is a mechanical device that extrudes materials into granules through high-speed rotating teeth, widely used in organic fertilizer, compound fertilizer and other fertilizer production fields, with significant advantages such as high granulation efficiency and good particle uniformity.

Working Principle

The tooth granulator completes the granulation process through three main steps:

Material Mixing: Thoroughly mix raw materials with binder

Extrusion Forming: High-speed rotating teeth extrude and shear materials

Particle Shaping: Form uniform granules through screen

Key Advantages

Selection Guide

Choose appropriate model based on capacity needs (Small:5-10t/h, Medium:10-15t/h, Large:15-20t/h)

Consider material characteristics: Match equipment performance with moisture content, viscosity etc.

Focus on key components: Tooth material (wear-resistant alloy steel recommended), motor power

Automation level: Modern equipment should have PLC control system

References:

International Fertilizer Equipment Association "Granulation Technology Guide" (2023)

Wang et al. "Advanced granulation technologies in fertilizer production" (2022)

0 notes

Text

Tube Furnace Manufacturer

At furnacemanufacturer, we take pride in being a trusted and leading Tube Furnace Manufacturer, providing high-quality, precision-engineered tube furnaces designed to meet the demanding needs of laboratories, research institutions, and industrial applications. With a commitment to innovation, durability, and customer satisfaction, we deliver advanced thermal processing solutions that exceed industry standards.

What is a Tube Furnace?

A tube furnace is an essential piece of equipment used for high-temperature heat treatment applications, such as material testing, sintering, calcination, annealing, and chemical vapor deposition. These furnaces consist of a cylindrical heating chamber with a heating element and a central tube, typically made of ceramic or quartz, through which samples are heated in a controlled atmosphere.

Why Choose furnacemanufacturer as Your Tube Furnace Manufacturer?

As a reputed Tube Furnace Manufacturer, we understand the critical role that heating systems play in various sectors such as metallurgy, ceramics, semiconductors, and academic research. Here’s what sets us apart:

1. Custom-Built Designs

We design and manufacture tube furnaces in various configurations including horizontal, vertical, and split-type models to suit specific client requirements. Our furnaces are available in single-zone, multi-zone, and gradient temperature zone options to ensure optimal thermal uniformity.

2. Wide Temperature Range

Our furnaces operate efficiently across a wide temperature range, typically from 300°C to 1800°C, depending on the model and the type of heating element used (Kanthal, molybdenum disilicide, or silicon carbide). This makes them suitable for a broad spectrum of scientific and industrial heating processes.

3. Energy Efficiency & Safety

We incorporate high-quality insulation materials and precision temperature control systems to ensure maximum energy efficiency. Safety features such as over-temperature protection, door interlocks, and digital controllers come standard with every furnace.

4. Advanced Control Systems

Our tube furnaces are equipped with user-friendly digital PID temperature controllers, programmable logic controllers (PLCs), and touchscreen HMI interfaces for accurate and automated operation. Remote monitoring and data logging capabilities are also available for quality assurance and compliance.

5. Robust Construction

Each furnace is built using corrosion-resistant materials and heavy-duty frames to ensure long-term durability and stable performance even under extreme conditions.

Applications of Our Tube Furnaces

As a top Tube Furnace Manufacturer, furnacemanufacturer caters to various industries including:

Research Laboratories – for testing material properties and thermal experiments.

Semiconductor Industry – for annealing wafers, oxidation, and diffusion processes.

Metallurgy – for sintering, brazing, and other high-temperature treatments.

Chemical Processing – for pyrolysis and decomposition of chemical compounds.

Ceramics & Glass – for firing and heat treatment of specialty materials.

Our Commitment to Quality & Support

At furnacemanufacturer, every product undergoes stringent quality checks and testing to ensure compliance with ISO and CE standards. Our experienced team provides technical guidance, customization, installation assistance, and prompt after-sales service to ensure smooth and hassle-free operation for our clients.

Global Reach, Local Support

With a strong distribution network and presence across major cities and industrial hubs, we serve clients both nationally and internationally. Our commitment to timely delivery, transparent communication, and affordable pricing makes us a preferred Tube Furnace Manufacturer among clients worldwide.

Get in Touch

If you are looking for a reliable and experienced Tube Furnace Manufacturer, trust furnacemanufacturer to deliver tailored heating solutions that enhance your productivity and research capabilities. Contact us today for a free consultation, product brochure, or custom quote.

0 notes

Text

Precision in Every Mix: The Power of Automatic Batching Systems

In the realm of industrial processing—whether in food production, pharmaceuticals, construction, or chemical manufacturing—precision isn't just a goal, it's a necessity. The automatic batching system (ABS) has emerged as a key innovation in achieving this precision, offering automated control of ingredient measurement, mixing, and record-keeping. By minimizing human error and increasing consistency, these systems are transforming how products are made around the globe.Get more news about automatic batching system,you can vist our website!

What Is an Automatic Batching System?

An automatic batching system is a computerized solution that automates the weighing and distribution of raw materials in specified proportions. These materials might include powders, granules, liquids, or gases depending on the industry. At its core, the system controls the sequence, quantity, and timing of material input to ensure a repeatable, high-quality output—be it concrete, dough, fertilizer, or medication.

The system typically integrates load cells, storage hoppers, conveyors, mixers, and programmable logic controllers (PLCs) to execute commands and monitor performance in real time.

Key Benefits Across Industries

The advantages of using an automatic batching system are multifold:

Improved Accuracy: Automated weighing and dosing eliminates the inconsistencies of manual measurement, ensuring consistent product quality.

Time Efficiency: Automated sequencing accelerates batch cycles, optimizing production time without compromising precision.

Data Traceability: Built-in software records every batch’s recipe and performance metrics, useful for quality control and regulatory compliance.

Reduced Waste: Efficient resource management minimizes overuse or spillage of costly materials.

Labor Savings: Automation reduces the need for manual oversight, allowing staff to focus on higher-value tasks.

In industries like food processing, this technology ensures that every loaf of bread or bottle of sauce meets exact taste and texture standards. In pharmaceuticals, strict compliance with ingredient ratios is critical to ensure drug safety. Meanwhile, the construction sector uses these systems to achieve precise mixtures of concrete or asphalt, essential for structural integrity.

Components and Workflow

A typical ABS begins with material identification—receiving commands either from a central SCADA system or manually selected recipes. The system then activates feeders or valves that dispense the correct quantity of each component into a scale or mixer. Once batched, the mixture is delivered to the next processing stage.

Safety protocols such as alarms, interlocks, and emergency stop mechanisms are standard to prevent overloads, cross-contamination, or mechanical faults.

Digital Integration and Innovation

Modern automatic batching systems increasingly leverage IoT (Internet of Things) and cloud technologies. Operators can remotely monitor batching status, adjust parameters, or receive alerts about anomalies. Some advanced setups include predictive maintenance capabilities powered by AI, which minimize downtime by identifying wear and tear before failure occurs.

Additionally, multilingual interfaces, recipe libraries, and batch comparison tools are making the systems more user-friendly and globally adaptable.

Outlook and Applications

As sustainability and production transparency become more important, automatic batching systems will play a pivotal role in helping manufacturers reduce energy consumption and optimize resource utilization. Their ability to ensure repeatable results while minimizing human error makes them indispensable in industries striving for consistent output and rigorous quality standards.

With global competition intensifying and regulations tightening, the implementation of automatic batching systems is no longer a luxury—it’s a strategic imperative.

Conclusion

In essence, automatic batching systems are the quiet drivers of precision manufacturing. They bridge the gap between raw material handling and finished product excellence. As industries evolve and demand greater efficiency, ABS technology will continue to provide the foundation for smarter, faster, and more sustainable production.

0 notes

Text

U.S. Meter Sockets Market Size, Share, Trends, Key Drivers, Demand and Opportunities

Executive Summary U.S. Meter Sockets Market :

Data Bridge Market Research analyses that the U.S. meter sockets market is expected to reach a value of USD 10,403.36 million by 2031, at a CAGR of 6.8% during the forecast period. The U.S. meter sockets market report also comprehensively covers pricing analysis, patent analysis, and technological advancements.

Transparent, trustworthy and extensive market information and data included in this report will definitely help develop business and improve return on investment (ROI). This U.S. Meter Sockets Market report provides an exhaustive survey of key players in the market which is based on a range of objectives of an organization such as profiling, the product outline, the quantity of production, required raw material, and the financial health of an organization. One of the sections in the report covers evaluation of probabilities of the new investment projects and overall research conclusions are offered.

U.S. Meter Sockets Market report helps the firm in exploring new uses and new markets for its existing products and thereby, increasing the demand for its products. This global market report offers research and consulting services focused on achieving competitive leverage, with acquiring and preserving market position as key aims of the program. The base year for calculation in the report is taken as 2017 and the historic year is 2016 which will tell you how the U.S. Meter Sockets Market is going to perform in the forecast years by informing you what the market definition, classifications, applications, and engagements are.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive U.S. Meter Sockets Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/us-meter-sockets-market

U.S. Meter Sockets Market Overview

**Segments**

- By Material: The U.S. meter sockets market can be segmented by material into stainless steel, aluminum, and others. Stainless steel meter sockets are known for their durability and resistance to corrosion, making them a popular choice for outdoor installations. Aluminum meter sockets, on the other hand, are lightweight and cost-effective, making them suitable for various residential applications. - By Application: In terms of application, the market can be divided into residential, commercial, and industrial segments. The residential segment dominates the market due to the increasing demand for smart meters and the renovation of existing infrastructure. The commercial and industrial segments are also witnessing growth as businesses focus on energy management and efficiency.

**Market Players**

- Eaton Corporation plc: Eaton is a key player in the U.S. meter sockets market, offering a wide range of products that cater to different customer needs. The company's focus on innovation and technology has enabled it to maintain a strong position in the market. - Schneider Electric: Schneider Electric is another prominent player in the market, known for its sustainable energy solutions and smart metering products. The company's emphasis on sustainable practices and energy efficiency has helped it gain a competitive edge in the market. - ABB: ABB is a global leader in power and automation technologies, including meter sockets. The company's focus on digitalization and smart grid solutions has positioned it as a key player in the U.S. market. - Siemens: Siemens is a well-established player in the meter sockets market, offering a range of products that meet the needs of residential, commercial, and industrial customers. The company's commitment to innovation and sustainability has helped it maintain a strong presence in the market.

The U.S. meter sockets market is poised for significant growth in the coming years as the demand for efficient energy management solutions continues to rise across residential, commercial, and industrial sectors. One of the emerging trends within the market is the increasing focus on sustainability and energy efficiency. Market players are investing heavily in developing smart metering products that not only provide accurate and real-time data but also help consumers and businesses optimize their energy consumption. This trend is being driven by stringent regulations aimed at reducing carbon emissions and promoting sustainability in the energy sector.

Another key trend shaping the U.S. meter sockets market is the rapid adoption of digitalization and smart grid technologies. As the need for reliable and secure energy distribution systems grows, there is a rising demand for advanced metering solutions that can support two-way communication between utilities and consumers. This shift towards smart grid technologies is expected to drive the market for meter sockets as utilities and energy providers seek to modernize their infrastructure and improve grid efficiency.

Furthermore, the market is witnessing a surge in investments in research and development activities focused on enhancing the performance and functionality of meter sockets. Market players are increasingly focusing on developing next-generation meter sockets that offer improved durability, connectivity, and data analytics capabilities. These advancements are aimed at meeting the evolving needs of consumers and businesses in a rapidly changing energy landscape.

One of the challenges facing the U.S. meter sockets market is the presence of stringent regulations and standards governing the installation and operation of metering devices. Compliance with regulatory requirements poses a significant challenge for market players, as non-compliance can lead to fines and penalties. To address this challenge, companies operating in the market are investing in technologies that ensure regulatory compliance and improve the overall efficiency and accuracy of metering systems.

In conclusion, the U.S. meter sockets market is witnessing robust growth driven by factors such as increasing demand for energy management solutions, adoption of smart grid technologies, and focus on sustainability and efficiency. Market players are actively engaged in developing innovative products and solutions to meet the evolving needs of consumers and businesses, positioning the market for sustained growth in the future.The U.S. meter sockets market is experiencing a profound transformation as technological advancements and changing consumer preferences shape the industry landscape. One of the noteworthy trends in the market is the increasing convergence of meter sockets with smart technologies, enabling real-time monitoring and data analytics for enhanced energy management. This shift towards smart metering solutions reflects a growing demand for more efficient and sustainable energy practices across residential, commercial, and industrial sectors. Market players are responding to this trend by investing in R&D to develop innovative meter socket products that not only ensure accurate metering but also contribute to better energy optimization and cost savings for end-users.

Moreover, sustainability is emerging as a key driving force in the U.S. meter sockets market, with both consumers and businesses showing a heightened interest in energy-efficient solutions. As environmental concerns continue to escalate, there is a pressing need for meter socket manufacturers to focus on eco-friendly materials and energy-efficient designs. This shift towards sustainable practices aligns with regulatory initiatives aimed at reducing carbon emissions and fostering a greener energy ecosystem. Market players are increasingly incorporating sustainability features into their meter socket offerings to cater to the evolving demands of environmentally conscious customers.

Another significant aspect impacting the U.S. meter sockets market is the expansion of digitalization and smart grid technologies. The integration of smart grid solutions is revolutionizing the energy sector by enabling seamless communication between utilities and consumers, thereby facilitating more efficient energy distribution and consumption patterns. This digital transformation is reshaping the meter sockets market, driving the adoption of advanced metering infrastructure and fostering greater grid reliability and resilience. Market players are leveraging these technological advancements to develop intelligent meter socket solutions that can address the complex energy management requirements of modern infrastructure.

Furthermore, alongside the opportunities presented by technological innovations and sustainability trends, market players in the U.S. meter sockets industry are also grappling with regulatory challenges and compliance issues. The stringent regulations governing metering devices necessitate a rigorous approach to product development and operational practices to ensure adherence to legal requirements. Companies operating in this market are focusing on enhancing their regulatory compliance mechanisms and investing in technologies that enable seamless integration with existing grid systems while meeting stringent industry standards.

In essence, the U.S. meter sockets market is poised for dynamic growth driven by the intersection of smart technologies, sustainability imperatives, and regulatory dynamics. Market players are strategically positioned to capitalize on these trends by offering cutting-edge meter socket solutions that cater to the evolving needs of energy consumers and support the transition towards a more sustainable and efficient energy landscape. The market's trajectory towards innovation and sustainability underscores its resilience and potential for long-term expansion in the face of evolving market dynamics and consumer expectations.

The U.S. Meter Sockets Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/us-meter-sockets-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Table of Contents:

U.S. Meter Sockets Market Overview

Economic Impact on Industry

Competition by Manufacturers

Production, Revenue (Value) by Region

Supply (Production), Consumption, Export, Import by Regions

Production, Revenue (Value), Price Trend by Type

Market by Application

Manufacturing Cost Analysis

Industrial Chain, Sourcing Strategy and Downstream Buyers

U.S. Meter Sockets Market Strategy Analysis, Distributors/Traders

U.S. Meter Sockets Market Effect Factors Analysis

U.S. Meter Sockets Market Forecast

Appendix

Browse More Reports:

Global Digital Holographic Display Market Global Animal Feed Acidifier Market Global Polyvinyl Butyral Market Global Lyme Disease Drug Market Asia-Pacific Reverse Logistics Market Middle East and Africa Remote Patient Monitoring and Care Market Global Hepatitis C Diagnosis and Treatment Market Global Sleep Tech Devices Market Global Paperboard Beverage Packaging Market Global Single-use Bioprocessing Systems Market Global Nanobots Market Global Oxidative Stress Assay Instruments Market Global Plastic Baby Food Packaging Market North America Conversational AI Market Global In-Memory Computing Market North America Reverse Logistics Market Global Imaging Infrared Light Emitting Diode (LED) Market Global Inherited Retinal Diseases Market Global Broadband Internet Access Services Market Global Plant Based Food Packaging Market Global Rare Earth Elements Market Global Automotive Natural Gas Vehicle Market North America Automotive DC-DC Converters Market Europe Non-stick Cookware Market Global Connected Care Market Global Triple A Syndrome Treatment Market North America Fluoroscopy - C Arms Market Global Video Conferencing Systems Market Global Automotive DC-DC Converters Market Global High Performance Lubricant Market North America Clinical Chemistry Analyser Market Global Performance Chemicals Market Global Vehicle Diagnostics Market Global Meatless Flavor Additives Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag:- U.S. Meter Sockets, U.S. Meter Sockets Size, U.S. Meter Sockets Share, U.S. Meter Sockets Growth

0 notes

Text

Advanced PLC and HMI Training Kits Manufacturer in Pune India

Leading Manufacturer and Supplier of advanced PLC and HMI training kits in Pune. Offering Siemens, Mitsubishi, and SCADA kits for hands-on industrial automation learning.

#Advanced PLC and HMI Training Kit Pune#Advanced PLC HMI Kits Pune#Advanced Siemens PLC Kits Pune#Advanced Mitsubishi PLC Training Pune#PLC and HMI Systems Pune#Industrial Automation Training Kits Pune#PLC and HMI Training Solutions Pune#Professional PLC Training Kits Pune#Advanced Automation Training Kits Pune#Best PLC and HMI Training Kits Pune.

0 notes

Text

Reliable PLC Panel Manufacturer for Industrial Needs - Burak Electric

Enhance your plant automation with our technically advanced PLC Panels. Built by a leading Programmable Logic Controller Panel Manufacturer, these panels offer seamless process control, real-time monitoring, and flexible integration with SCADA or HMI. Suitable for manufacturing, water treatment, and power plants, they are fully customizable to meet your operation's demands with high safety standards.

0 notes

Text

What energy-saving designs does the organic fertilizer coating machine have

The energy-saving design of organic fertilizer coating machines is mainly reflected in the following aspects:

1. Optimization of hot air system: Some organic fertilizer coating machines adopt waste heat recovery technology to recover and utilize the heat generated during the fermentation process for preheating the feed or heating other production stages, reducing energy waste. Through the hot air circulation system, hot air is recycled within the equipment to enhance the efficiency of thermal energy utilization and reduce energy consumption.

2. Automation and intelligent control: Modern organic fertilizer coating machines are equipped with PLC control systems, which can automatically adjust parameters such as rotational speed, spray volume, and temperature according to the production requirements of the organic fertilizer production line, achieving precise control and optimized management. Organic fertilizer equipment can automatically switch to energy-saving mode according to actual production needs, reducing energy consumption.

3. High-efficiency spraying system: Advanced spraying technology is adopted to ensure that the coating material is evenly covered on the surface of the fertilizer particles, reducing material waste. The coating liquid is atomized and sprayed onto the particle surface by using high-pressure nozzles to improve the spraying efficiency and reduce energy consumption.

4. Material selection and equipment design: The main unit is lined with polypropylene or acid-resistant stainless steel to enhance the equipment's corrosion resistance and service life. According to the process requirements, a special design was made in the internal structure to improve the operational efficiency of the equipment.

5. Drying and curing assistance: Some equipment is equipped with a hot air system to accelerate the drying or curing of the coating material, reduce drying time, and enhance production efficiency. It adopts a double-layer cylinder design, with the inner layer being coated and the outer layer being dried, which improves the drying efficiency.

Through the above energy-saving design, the organic fertilizer coating machine can not only improve production efficiency but also significantly reduce energy consumption, achieving a win-win situation of environmental protection and economic benefits.

0 notes

Text

From Classroom to Lab: Exploring SUAS’s Specialized Robotics & Automation Labs

At the heart of engineering excellence is the ability to build, test, and innovate — and that’s exactly what students at Symbiosis University of Applied Sciences, Indore (SUAS) experience every day. As a modern private university in Indore, SUAS blends academic knowledge with practical expertise, especially in its B.Tech in Automation & Robotics program. But what truly sets SUAS apart is its world-class laboratory infrastructure, designed to mirror the most advanced industry settings.

Real-World Learning Begins in the Lab

While many universities emphasize theory, Indore Symbiosis focuses on real-world application. Students spend a significant portion of their time in specialized labs, engaging with the same equipment, tools, and technologies used by industry professionals. SUAS follows a 70:30 model — 70% practical learning and 30% theoretical instruction — making it one of the top universities in Indore for hands-on engineering education.

Key Laboratories at SUAS

🔧 Automation Lab

This lab gives students access to industrial automation components like programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, and actuators. Here, students simulate and implement automated systems just as they would in automotive, manufacturing, or packaging industries.

🤖 Robotics Lab

Equipped with robotic arms, Arduino kits, and programmable systems, this lab allows students to build and test robots from scratch. They learn everything from robotic movement and path planning to vision-guided robotics and AI integration.

⚙️ Microprocessors & Embedded Systems Lab

Students get hands-on with microcontrollers like 8051, PIC, and ARM boards, learning how to build embedded systems — the backbone of smart robots and automation devices. The lab supports courses in embedded C, IoT systems, and device-level programming.

🛠️ Lucas-Nülle Lab Setup

Through international collaboration, SUAS integrates Lucas-Nülle’s Germany-based training systems, known for bridging academic learning with practical engineering. These systems simulate real industrial environments and enhance technical training to a global standard.

Innovation Starts Here

Labs at SUAS are not just for coursework. Students regularly use them for capstone projects, hackathons, and startup prototypes — from 3D-printed robotic parts to drones and home automation systems. Supported by SUAS’s incubation center and mentorship programs, students can transform classroom ideas into real innovations.

Why It Matters

In a field like automation and robotics, real lab exposure gives students a serious edge. They not only understand theoretical models but can also wire, program, and troubleshoot physical systems — a skillset highly prized by employers in India and abroad.

Conclusion

For aspiring engineers seeking the perfect blend of academic learning and hands-on experience, Symbiosis University of Applied Sciences, Indore delivers through its specialized labs and industry-driven curriculum. It’s no wonder SUAS is widely regarded as one of the best universities in Indore for engineering in the automation era.

0 notes